|

U.C. Berkeley Sack Lifter

Premise: Professor Kazerooni's Lab at Cal had a refined system for assisting people's lifting strength, assuming the object to be lifted could be secured by the machinery. Buckets and pallettes are easy because there are handles and straps to hook, but one client had a need to lift heavy sacks from a disorganized pile. There were 5 or 6 different types of sacks, with different features and materials. How do you grab sacks with a machine? Approach: Lots of ideas were batted around- vacuum pad, a robot hand, a simple gripper, a gripper with vacuum, a gripper with tiny needles and so on. But sacks are uncertain- how slick is the material, how taut is it, how porous is it, how heavy is the sack?

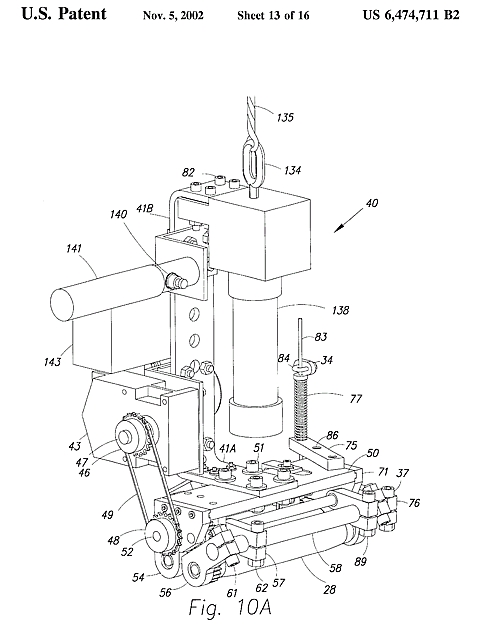

Answer:We knew if there was a way to get material in between two surfaces (like thumb and forefringer), the rest was easy to predict, but all these anatomy-based ideas were too complex to even try quickly, let alone manufacture. An opposing roller idea was attractive but there was no quick way to model how the rollers might (or might not) gather material. The first sack grabber took about 2 hours to build. It was made of rusty welded metal, a door hinge, springs, dowels, rubber, staples, cut up hex wrenches and an electric drill. It worked very well; just touching it against a sack gobbled the material right into the rollers. We were able to proceed on the design with confidence that it would work. U.S. Patent 6,474,711 is the result. |

|

|