|

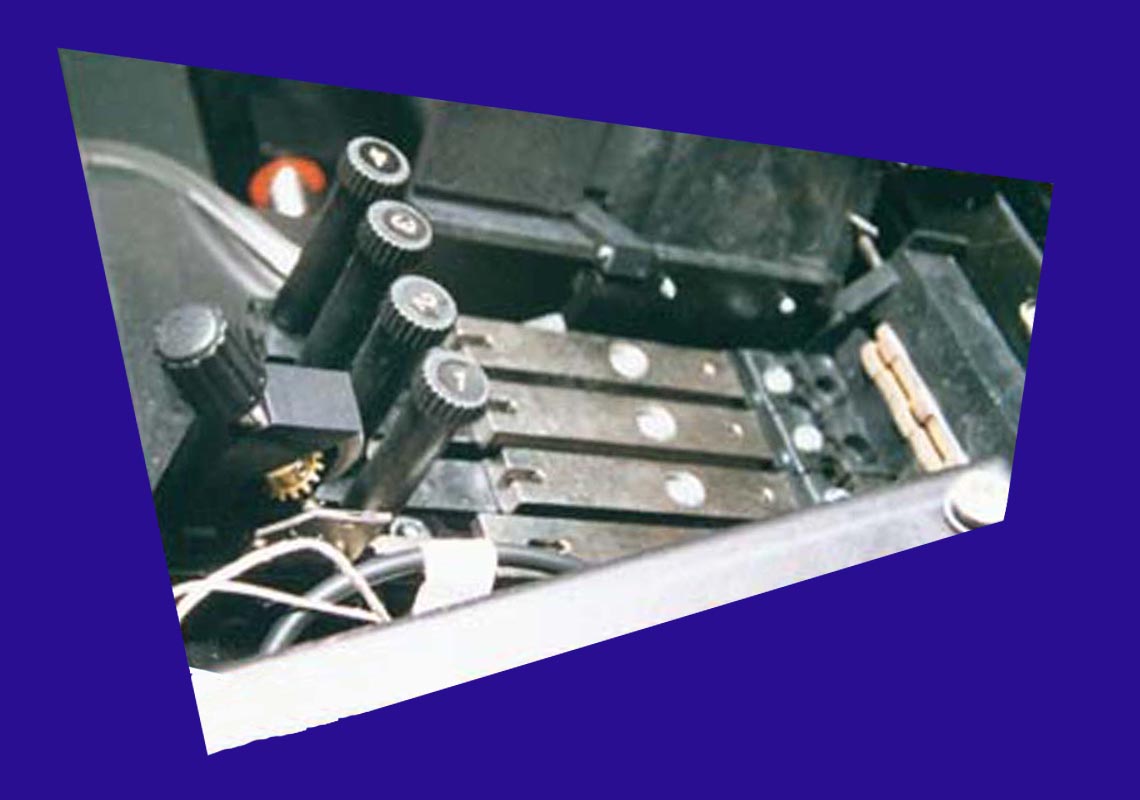

Intro: When I was working at Iris Graphics, their CMYK 4012 inkjet printer was the highest resolution color printer in the world, albiet slow. The saavy marketers there realized that if we printed with 2 black and 2 grey inkjets instead, we could print in beautiful grey scale twice as fast, and the medical market could make multiple film quality prints of X-rays and MRIs. Problem: Our printing technology threw ink a whole 3/4 inch from the nozzle to the paper. With routine calibration, repeatability was good, but accuracy was not. Any ink drops more than 20 microns out of horizontal alignment would create a streaky image on the paper. Solution: Luckily the printer could measure the targeting error of each jet. It would measure both pairs of jets, accept the two black jet placements as they were, and tell the operator to dial in the grey jets to match. This is where my design came into the picture. I made a mechanism with a knob for the operator to turn and it had a small spur gear and follower that created a perceptible click for each 5 microns of adjustment. After calibration, the LCD display told the operator to turn the knob something like 18 clicks clockwise, bringing the 2 grey jets into alignment. This sounds absurd now, but in 1993 it was not. It worked, and we sold 50 or 100 of these printers. This was my first job out of college and was an eye opener about putting things into production. What seemed obvious to me was not obvious to the people assembling my stuff on the floor. I learned how to use drawings, pictures and detailed instructions to make assembly procedures clear. |

|

|