|

Hovermatic |

|

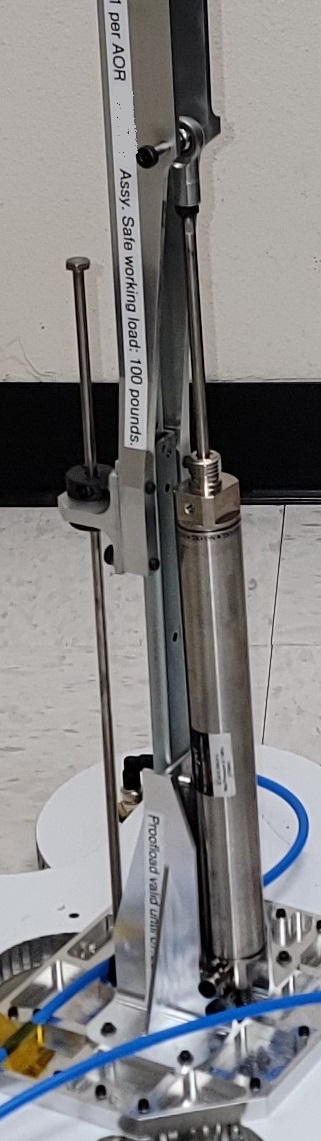

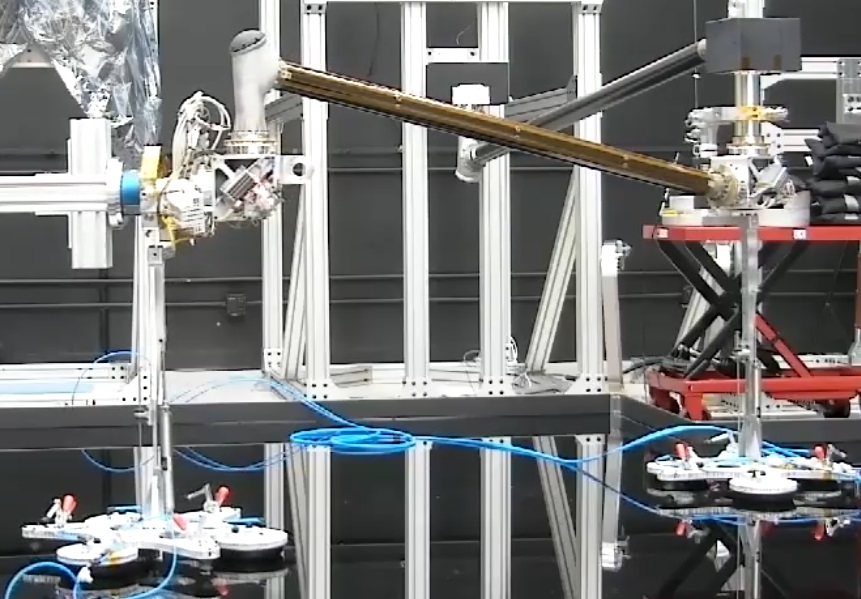

Smooth Constant Upforce To simulate zero g, the competing concept used a clock spring and cam to create nearly constant upforce. I do not remember how the force was adjusted. Airpel cylinders are designed to leak slighlty through gapped seals. I'd used them before and they are virtually frictionless. Add a COTS McMaster linear ball stage and an air pressure regulator and boom, adjustable constant upforce over a 5 inch range. Supplied with full documentation (all drawings, procedures and BOM), the courageous Maxar technicians who endured pandemic policies on-site were able to get this thing together with only my remote help. /s. Honestly not my favorite way to work but there you go. |